Build Your Dream Pallet Shed: A Beginner's Guide

Hey there, fellow DIY enthusiasts! So you're thinking about building a shed, but the prices at the home improvement store are making your eyes water? Don't worry, you're not alone! That's why I'm here to share my secrets on building a super reliable, surprisingly stylish, and totally affordable pallet shed. This guide is perfect for beginners â€" no fancy tools or years of experience needed! Let's get started!Step 1: Gathering Your Materials â€" The Pallet Hunt Begins!

The beauty of a pallet shed lies in its resourcefulness. The star of the show? Pallets! Now, before you start picturing yourself scavenging behind supermarkets at midnight (although, that could be fun!), let's talk strategy.Finding Your Perfect Pallets

*Choosing the Right Pallets

Not all pallets are created equal. Look for: *Aim for at least 10-15 pallets, depending on the size of the shed you envision. It's better to have a few extra than to run short in the middle of the project.

Step 2: Preparing Your Pallets â€" A Little TLC Goes a Long Way

Before you start building, your pallets need a little prep work.Cleaning and Repairing

Give your pallets a good cleaning. Use a stiff brush, a pressure washer (if you have one), and some soap to remove dirt, debris, and any lingering grime. Repair any damaged boards using wood glue and screws. Replace severely damaged boards if necessary.

Disassembling (Optional but Recommended)

While you *can* build your shed directly with the pallets intact, disassembling them offers several advantages: It allows for more precise construction and gives you greater flexibility in designing your shed. Plus, it makes it easier to address any damaged sections.

Step 3: Building the Foundation â€" A Solid Base for Your Masterpiece

Your shed needs a sturdy foundation. This could be as simple as a concrete slab (if you're feeling ambitious!), or a more budget-friendly option like a gravel base. For this beginner's guide, we'll go with a gravel base.

Creating the Gravel Base

- Clear the area where you want to build your shed. Remove any grass, weeds, or debris.

- Level the ground as much as possible. A slightly uneven surface is okay, but major dips or bumps need to be addressed.

- Lay down a layer of landscaping fabric to prevent weeds from growing up through the gravel.

- Spread a 4-6 inch layer of gravel over the fabric. Compact it down using a tamper or even just your feet.

Step 4: Assembling the Walls â€" Putting it All Together

Now comes the fun part! This is where you'll use your prepared pallets to construct the walls of your shed. Remember, you have the option of using whole pallets or individual boards. If you're using whole pallets, ensure they're securely fastened together.

Wall Construction Tips

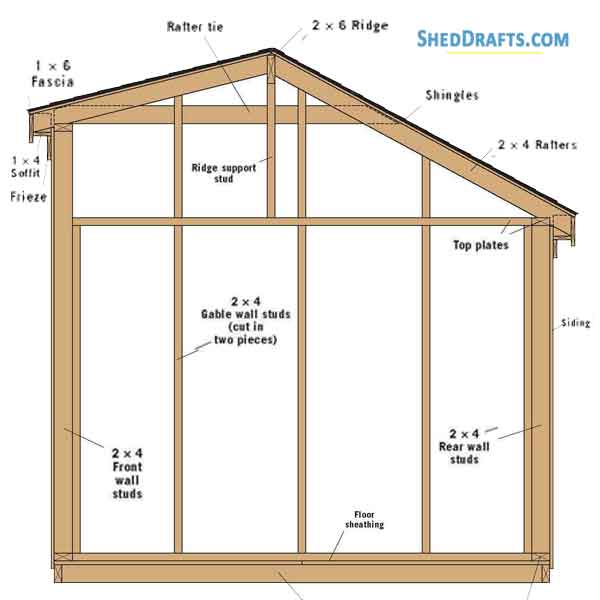

*Step 5: Building the Roof â€" Shelter from the Storm

For a simple roof, consider a lean-to style or a gable roof (two slanted sides meeting at a peak). You can use plywood, corrugated metal sheets, or even more pallets for the roofing material. Remember to waterproof your roof.

Step 6: Adding the Finishing Touches â€" Personalization Time!

Once your shed is structurally sound, it's time for the fun stuff! Add a door, windows, shelvesâ€"whatever you need to personalize your space. Consider painting your shed for extra protection and aesthetics. A coat of stain can also add a rustic charm.

Frequently Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends on the size and complexity of your shed, as well as your experience level. A simple shed could take a weekend, while a more elaborate one might take several weekends.

Q: Do I need special tools?

A: While a basic toolkit will suffice, power tools like a drill and a saw will significantly speed up the process. A level is essential for ensuring straight walls.

Q: How do I make my pallet shed weatherproof?

A: Use weatherproof sealant on the wood, a waterproof roofing material, and consider adding gutters and downspouts to direct rainwater away from the shed.

Q: Can I use treated pallets?

A: While you can, it's generally recommended to avoid chemically treated pallets ("MB" stamp) due to potential health concerns. Heat-treated pallets ("HT" stamp) are the safer option.

Q: What can I store in my pallet shed?

A: This depends on the size and sturdiness of your shed! You can store garden tools, outdoor equipment, bicycles, wood, or even use it as a small workshop.

There you have it! Building a pallet shed is a rewarding project that combines creativity, resourcefulness, and a whole lot of fun. Remember to take your time, follow safety precautions, and most importantly, have fun! Happy building!